|

|

|

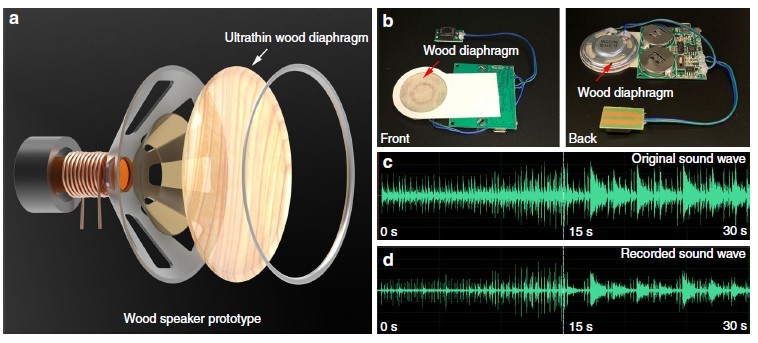

Image: Wood speaker prototype: a) Schematic of the wood speaker prototype. B) Photographs of the speaker with the wood diaphragm. C) The sound wave of the original song (Spain Matador March). D) The recorded sound wave (Spain Matador March) of the speaker with the wood diaphragm. |

|

In recent history, much effort has been put into the development of thin film materials for use in acoustics technology as a means of amplifying sound quality. Plastic is most commonly used, although metal, ceramics and various carbon-based materials (e.g. graphene or charcoal) are also popular materials utilized in commercial speakers, including those used in vehicles, home electronics and even water treatment. The problem with these materials is that most of them are not biodegradable, require a complex manufacturing process that wastes significant amounts of energy, and they’re expensive to produce.

To that end, researchers at the University of Maryland have recently developed a super-thin wood speaker boasting high tensile strength and excellent acoustic properties, which offers a promising alternative to next-gen acoustic speakers. Chaoji Chen, a post-doctoral research associate in the Department of Materials Science and Engineering (MSE) at UMD, served as co-first author on the research paper published in Nature Communicaitons.

“In addition to the advantages of abundance and renewability, cellulose wood fibers offer extraordinary mechanical properties with a theoretical tensile strength up to 7.5 GPa and a Young’s modulus up to 120 GPa, which are even higher than those of common metals, ceramics and many composites,” said Chen.

The inherent structure of wood provides a unique alternative for “more scalable and mechanically robust cellulose films,” according to the study.

To build this ultrathin film from the top-down, the team cut the wood length-wise to maintain the channel structure, and partially removed the lignin and hemicellulose from balsa wood. Then, a highly porous material, retaining most of the cellulose in the cell walls, was created. The treated wood was then ‘hot pressed’ to force a thickness reduction of 97 percent. The team conducted a series of tensile tests, indicating nearly 20 times improvement of tensile strength over natural wood. Moreover, remarkable flexibility was observed, allowing the team to fold the wood into various origami shapes.

The researchers then tried the film on for size as an acoustic transducer, assembling a miniature speaker. The sample contained the wood diaphragm, and a circuit board with a small speaker containing a copper coil and magnet. The soundwaves generated were analyzed using Adobe Audition CC and the team played a recording of the Spanish Matador March.

The research team – led by MSE Professor Liangbing Hu and UMD Mechanical Engineering Professor Miao Yu – expects to further improve the prototype design, which will hopefully translate into the manufacturing of goods such as microphones, hearing aids and acoustic sensors.

For additional information:

Gan, W., Chen, C., Kim, H. et al. (2019, Nov). “Single-digit-micrometer thickness wood speaker.” Nature Communications, 10, 5084 (2019). DOI: 10.1038/s41467-019-13053-0

Related Articles:

UMD to Host International Seminar on Sustainability

Wood-based Technology Creates Electricity from Heat

With Engineering Projects, UMD Students Seek to Boost Education Access, Public Health, and Sustainability

Davis to Serve as Faculty Mentor for NSF-Funded Global STEWARDS Program

Super Wood Could Replace Steel

UMD Researchers Work to Mitigate Water Scarcity Crisis with Solar-Powered Devices Made of Wood

Wood filter removes toxic dye from water

UMD Teams Awarded Over $5 Million to Improve Power Plant Cooling Technologies

A Battery Made of Wood?

How Hot is Solar Energy?

February 13, 2020

|