|

Assistant Professor Siddhartha Das publishes joint research outlining new method to synthesize Metal Chalcogenides Nanostructures.

Department of Mechanical Engineering Assistant Professor Siddhartha Das and Materials Science and Engineering Assistant Professor Liangbing Hu have collaborated with researchers from Auburn University and Youngstown State University to develop a new surface-physics-driven nanomanufacturing technique for ultrafast and energy-efficient single step process for synthesizing Metal Chalcogenides (MCs) Nanostructures. The findings, published in Scientific Reports of Nature Publishing Group, can potentially revolutionize the techniques for producing metal chalcogenides that are widely used in applications ranging from energy storage and catalysis to lubrication and electronics. The leading author for the paper is Dr. Zhen Liu, who has been a recipient of the Chinese government award for outstanding students abroad, a DARPA postdoc fellow with Prof. Hu and a former PhD student of Prof. Xinyu Zhang (lead contributor of this work from Auburn University).

MCs represent a particular class of nanostructures, where there is at least one chalcogen anion (like oxygen, sulfur, selenium, tellurium, and polonium) and an electropositive element (such as metals). These MC nanostructures have potential for use in lithium ion batteries, fuel cells, solar cells, supercapacitors, and opto-electronic devices as well as for electrochemical water-splitting and chemical catalysis.

Among the most popular members of this MCs family are MoS2 (Molybdenum disulfide) and WS2 (Tungsten disulfide). In the existing methods for fabrication of these MCs, there are several substantial bottlenecks, such as presence of extreme reaction conditions (e.g., high temperature, argon protection), use of hazardous chemicals (such as organic solutions), involvement of expensive facilities, etc. The nanomanufacturing technique discovered by the team is unique in its capabilities in the sense that it overcomes all these bottlenecks and proposes a technique to synthesize nanostructured MCs in the most facile and highly energy-efficient approach. The technique involves simple microwave heating of the chemicals (that provide the constituents of the MCs) placed on nanostructured organic conductor, i.e., polypyrrole nanofibers (PPy-NF). These nanofibers are able to to absorb the microwave energy to heat the chemicals, thereby eventually generating MCs as nanoparticles. The key issue here is the single step formation of MCs in an approach that is way more energy-efficient and fast as compared to any other existing process used for synthesis of MCs. Equally important, the study establishes that this technique can be universally applied for synthesizing different kinds of MCs and Metal Oxides (MOs) (e.g., MoS2, WS2, and MoOx).

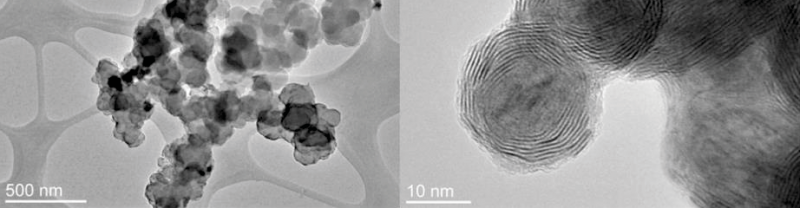

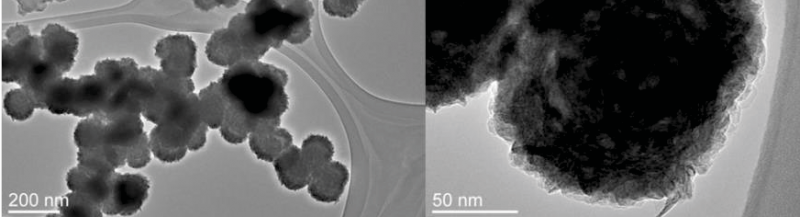

“Once formed as nanoparticles of dimensions of only few nanometers, these MC nanoparticles undergo a most intriguing nanoscale surface interaction to generate highly exotic nanostructures”, Das explained. “For example in case of MoS2, these NPs, under the action of the temperature-induced vibration, interact with each other in a manner such that the corresponding nanostructures appear as long two dimensional needle-like or onion-like rings; on the other hand, for MoOx these interactions lead to more of a bulk three dimensional structure”. Das points out that in either of the cases, it is the minimization of the free energy that dictates such exotic structures. More importantly, this understanding will provide a handle to control the nanoscale structures of the MCs possibly for the first time.

The team believes that many potential applications for MC nanostructures and the current lack of a convenient, energy-efficient technique that can controllably synthesize such MC nanostructures make their discovery timely. This new easy and energy-efficient technique for MC nanostructure synthesis will serve as a great vehicle to the research community on nanomaterials as they continue to research newer applications of the MC nanostructures.

Figure 1: TEM Images of MoS2 nanostructures grown on PPy-NF by microwave-heating-based nanomanufacturing (Figure taken from Liu et al., Scientific Reports, Vol. 6, pp. 22503, 2016)

Figure 2: TEM Images of WS2 nanostructures grown on PPy-NF by microwave-heating-based nanomanufacturing (Figure taken from Liu et al., Scientific Reports, Vol. 6, pp. 22503, 2016)

Related Articles:

ME Researchers Develop Methods to Mediate Nanoparticle Adhesion

UMD Researchers Discover Methods to Mediate Membrane-Nanoparticle Interactions

Exploration of Graphene's Wetting Dynamics Could Open New Possibilities in Fluid Mechanics of Two-Dimensional Materials

Drop-Drop Interactions on Soft Materials Unravel “Cheerios-Like” Behavior of Liquid Drops

Surfing Liquid Drops Shed New Light in Soft Materials Research

Das leads UMD undergraduate research team to publish cover article in Colloids and Surfaces B: Biointerfaces

March 3, 2016

|