|

|

|

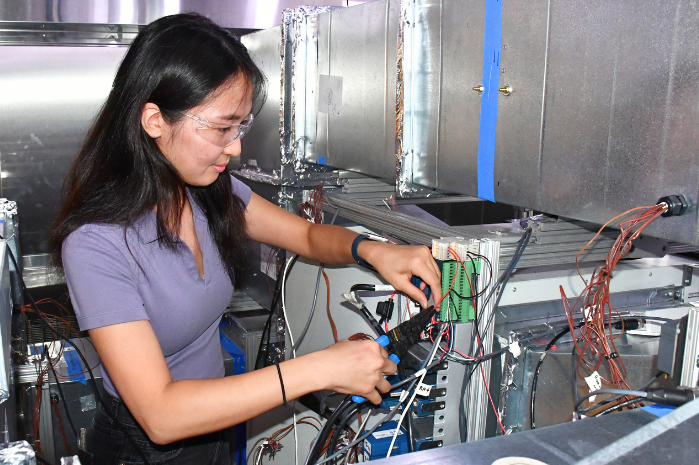

CEEE researchers are developing an energy-efficient, two-chamber wood-drying heat pump that will recover heat from the first chamber to warm the second. Graduate student Dana Kang connects sensors that will help control the heat recovery process. |

|

In a newly published paper, a research team led by the University of Maryland’s Center for Environmental Energy Engineering (CEEE) makes the case for developing heat pump technologies geared toward the wood-drying industry to help decarbonize the process of preparing lumber to be used for construction, furniture and more. In 2018, the U.S. wood products manufacturing sector emitted over 36 million metric tons of carbon dioxide, with 81% of on-site energy use coming from combustion processes. Electric heat pumps offer a promising decarbonizing solution.

The paper, published in the December 1 issue of Energy, offers a comprehensive review of the literature on two separate topics – wood-drying processes and heat pump technologies – as well as a look at the limited use of heat pumps in the wood-drying industry. “The vast majority of wood-drying relies on fuel combustion,” says CEEE postdoctoral researcher Andrew Fix, who is the paper’s co-first author along with former CEEE researcher Lei Gao, now on the R&D staff at Oak Ridge National Laboratory. “Heat pumps make up a very small fraction of the current wood-drying technology.”

The review paper bridges the gap between the wood-drying sector and the heat pump industry. “A heat pump expert can learn a lot about the specific needs of the wood-drying industry,” Fix says. “Meanwhile, a wood-drying expert, who is comfortable using conventional techniques like combustion-fueled wood-drying kilns, can learn about heat pumps and how they could be applicable.”

Graduate research assistant Tamoy Seabourne checks the heat pump control box. Graduate research assistant Tamoy Seabourne checks the heat pump control box.

The other co-authors are Tamoy Seabourne, Yong Pei, Yunho Hwang, Bao Yang, and Reinhard Radermacher, all with CEEE, and Patrick Adegbaye of the University of the District of Columbia.

As a next step, the research team is taking an innovative approach to making heat pumps more efficient for the wood-drying sector. As part of a $2.7 million Department of Energy-funded project, researchers are developing a two-chamber wood-drying heat pump that captures the waste heat from the first chamber and uses it to heat a second chamber, nearly doubling the heat pump’s efficiency. The eventual prototype will use refrigerants with low global warming potential, making the heat pump even more environmentally friendly.

“We really want to decarbonize the wood production process,” Fix says. “We're already cutting down trees, so that's taking out carbon sinks, and then we're burning more fossil fuels, emitting carbon dioxide. Heat pumps provide a great opportunity to decarbonize the process.”

Due to the novelty of the two-chamber wood-drying heat pump concept, the team has filed an invention disclosure with the University of Maryland. This is the first step in securing a patent.

Download the paper: “A comprehensive review of heat pump wood drying technologies.”

Related Articles:

Graduate Students Awarded Scholarships for HVAC&R Research

CEEE Research Professor Yunho Hwang to Receive Provost’s Excellence Award

DOE Ups Its Investment in UMD to Develop Eco-Friendly Heat Pumps

CEEE Co-Director Leads Global Webinar on Advances in Low-GWP Heat Pumps

CEEE Researcher Named Finalist in UMD’s 3MT Competition

October 22, 2024

|