|

As engineers seek out new ways of utilizing ceramic materials, many are looking to nature for guidance. Composite structures found in the natural world—such as nacre, also known as mother of pearl—have properties of toughness and damage resistance that ceramics lack on their own. As engineers seek out new ways of utilizing ceramic materials, many are looking to nature for guidance. Composite structures found in the natural world—such as nacre, also known as mother of pearl—have properties of toughness and damage resistance that ceramics lack on their own.

Now, an international, cross-institutional team that includes University of Maryland (UMD) mechanical engineering professor Teng Li and UMD postdoctoral researcher Zhengqian Pang has developed a promising approach to fabricating damage-tolerant, architected ceramic structures, by utilizing 3D printing and the application of a conformal polymer micro-coating. Now, an international, cross-institutional team that includes University of Maryland (UMD) mechanical engineering professor Teng Li and UMD postdoctoral researcher Zhengqian Pang has developed a promising approach to fabricating damage-tolerant, architected ceramic structures, by utilizing 3D printing and the application of a conformal polymer micro-coating.

Their work—which provides a simpler, more versatile alternative to existing methods of fabricating such structures—is detailed in the July 7 issue of Science Advances.

Ceramic materials have a multitude of applications. In the biomedical field, for instance, they can be used for bone substitutes, tissue engineering scaffolds, dentals, and surgical tools. Effective as they are, however, these materials have significant drawbacks: they are brittle and prone to fracturing, and are not very pliable.

Tough, fracture-resistant ceramic composites are commonly found in the natural world, however. Nacre is one example. Bones are another. Engineers have studied these structures and sought to fabricate similar ones using a variety of methods, including additive manufacturing.

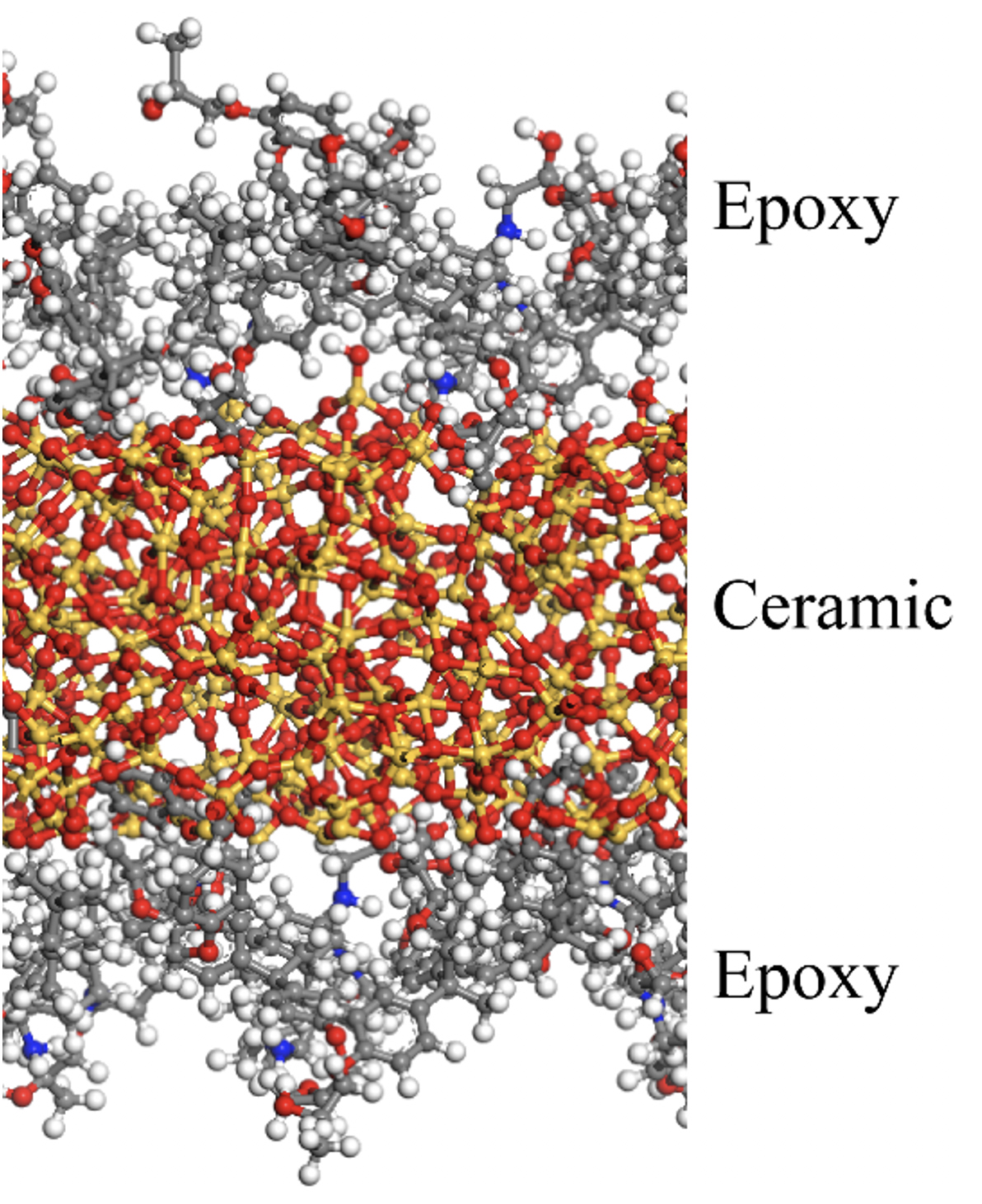

In their research, Li and his colleagues 3D-printed silica-filled preceramic polymer and then created a ceramic structure by pyrolyzing it; they then coated the ceramic material with a thin layer of flexible epoxy polymer. The mechanical behavior of the coated ceramic, including the initiation, propagation, and arresting of cracks, was studied and compared to that of uncoated ceramic. The team carried out atomistic modeling to reveal the strengthening and toughening mechanism of the epoxy-coated ceramic, and also analyzed different architectures and geometries to show the effect of coating for general applicability regardless of the core ceramic structures.

In addition to Li and Pang, the research team includes Seyed Mohammad Sajadi (Rice University), Lívia Vásárhelyi (University of Szeged), Reza Mousavi (ANSYS, Inc.), Amir Hossein Rahmati (University of Houston), Zoltán Kónya (University of Houston), Ákos Kukovecz (University of Szeged), Taib Arif (University of Toronto), Tobin Filleter (University of Toronto), Robert Vajtai (Rice University, University of Szeged), Peter Boul (Aramco Americas), Chandra Shekhar Tiwary (Indian Institute of Technology), Muhammad M. Rahman (Rice University), and Pulickel M. Ajayan (Rice University).

Findings from the study “could be extended to many structural applications, where simultaneous optimization of weight and mechanical performance of the ceramic is required,” the research team wrote.

July 8, 2021

|